Spray Pond Cooling Tower

Replacement cooling tower nozzles.

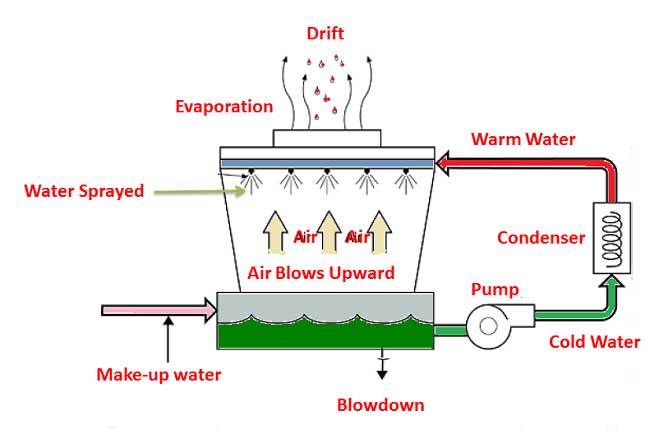

Spray pond cooling tower. The water is sprayed across the fill packaging. Cooling towers may either use the evaporation of water to remove process heat and cool the working fluid to near the wet bulb air temperature or in the case of closed circuit dry cooling towers rely solely on air to cool the working fluid to near. Heat that the cooling tower must reject from the water in the chiller is the cooling load of the conditioned area plus the heat. Thin film of condenser water.

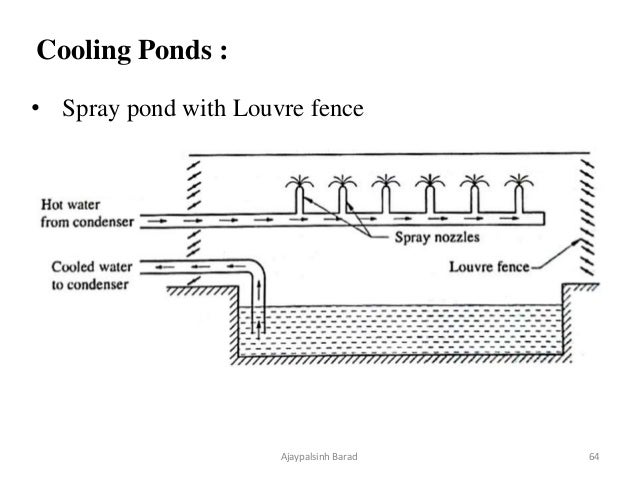

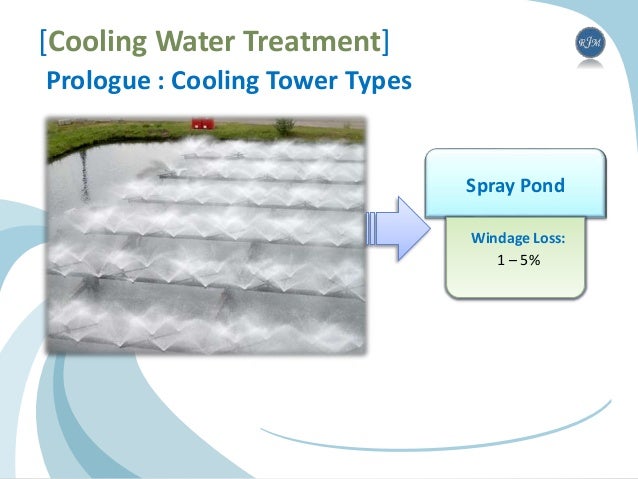

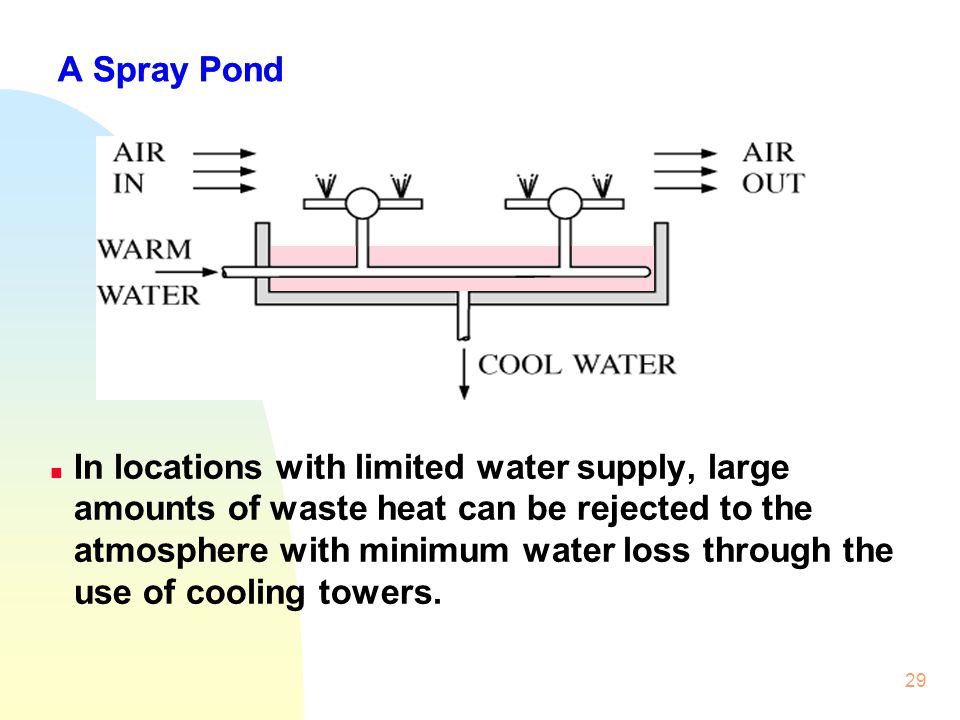

Different kinds of cooling tower spray nozzle from sara meet different brand cooling tower. We supply many types of nozzles for replacement such as spray nozzles with. Most of the cooling occurs by evaporation and only a small proportion is by sensible heat transfer. A spray pond requires between 25 and 50 times the area of a cooling tower.

Technician a says that a spray pond and an evaporative condenser are exactly the same. This is an ideal video for hvac power plant engine. From water vortexing b. The water will evaporate into the air and carry heat away with it.

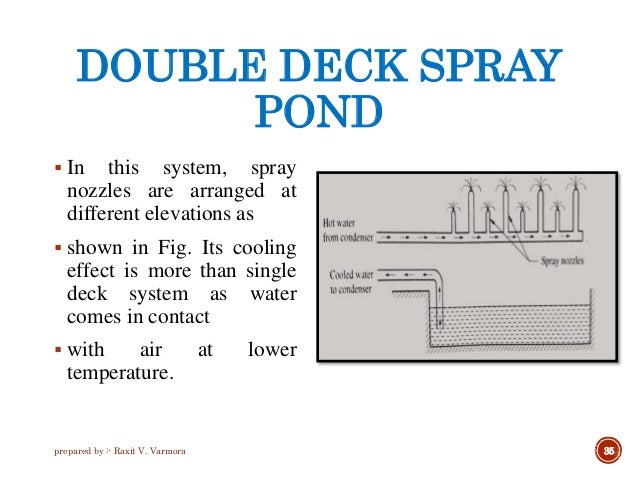

A cooling tower is a heat rejection device that rejects waste heat to the atmosphere through the cooling of a water stream to a lower temperature. These droplets from the spray run down the fill packaging causing a thin film of water on its surface. However some spray ponds are still in use today. In cooling towers or spray ponds the exchange of heat between the warm water and ambient air is by conduction between the fine droplets of water and the surrounding air evaporative cooling which is by far the most.

The water is cooled by contact with cooler ambient air either in conventional cooling towers or in spray ponds. Condenser water spray on to fill packaging. Technician b says that an evaporative condenser depends on the. This video explains how cooling towers work and the working principle behind all wet type cooling towers.

Thus a significant proportion of the condensed vapour is evaporated in the cooling system. The cooling process is carried out in cooling towers or spray ponds after which the water is pumped back to the condensers. We are a manufacturer and supplier of cooling tower nozzles. Not easy to block from water pipe to spray nozzle make a good temperature cooling.

The spray pond is the predecessor to the natural draft cooling tower which is much more efficient and takes up less space but has a much higher construction cost.