U Cup Seal Design Guide

Hydraulic sealing solutions for fluid power applications have become a priority in our continued product offering.

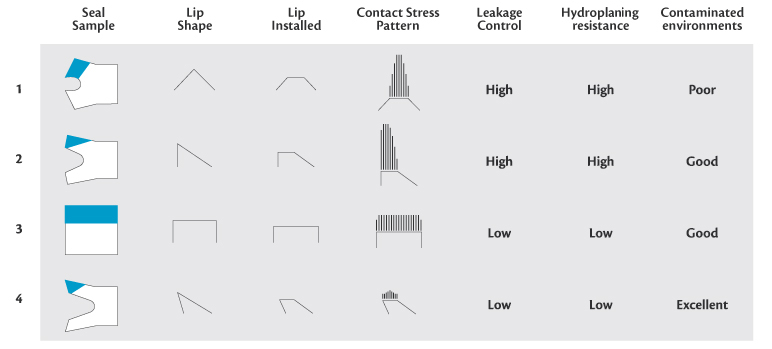

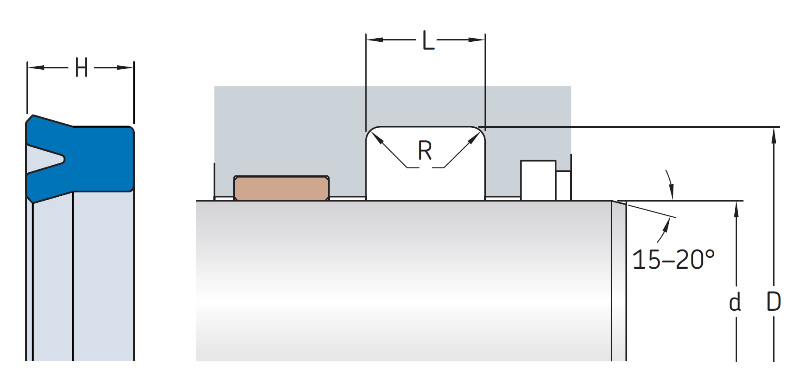

U cup seal design guide. They are used for both dynamic and static applications. Chamfers are used as a guide to aid seal installation. U cups are a lip seal named for the cross section s distinctive u shape. This brilliant design has been modified to create several unique configurations.

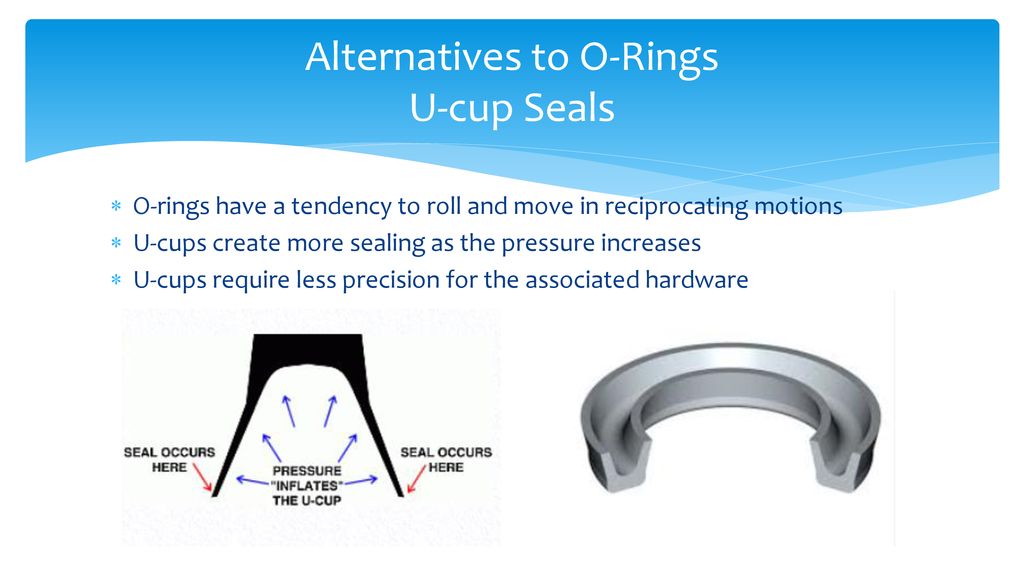

Head seals are a more reliable alternative to the standard o ring backup ring combination they resist twisting. Wear rings guide the rod and piston to prevent uneven wear and optimize seal performance. Head seals are a more reliable alternative to the standard o ring backup ring combination they resist twisting. Symmetrical metric u cup seal u cup seal 4mm id x 10mm od x 4 5mm ht high temp urethane seal excellent wear and abrasion resistance up to 5000 psi applications symetrical lip design they can be used in rod or piston applications price is.

U cup seals or u ring seals are commonly used in linear applications to seal the rod or piston. The u shape energizes the sealing lips as the application pressure increases. Many different ucup configurations exist to properly seal that demanding application. Rubber seals sealing devices o ring seal design apple.

Seals for additional recommendations. Mfp offers a wide range of metric u cup designs and produces them from a broad range of materials. Rod wipers scrape dirt dust and moisture from the rod preventing contamination inside your cylinder. Surface finishes that are too high or too low can reduce seal life.

The o ring store offers an assortment includes rod piston and wiper seals as well as guides o rings and back up rings. The a dimension shown below will allow the o ring loaded u cup to enter a cylinder bore and should be the minimum width designed. Rod wipers scrape dirt dust and moisture from the rod preventing contamination inside your cylinder. Leak free seal from hard vacuum to over 60 000 psi with proper design and auxiliary devices.

Fluid power seals sizes readily available in a multitude of materials to provide optimal compatibility with the various hydraulic fluids encountered in service. Rod seals maintain the pressure inside cylinders and prevent fluid from leaking out. Wear rings guide the rod and piston to prevent uneven wear and optimize seal performance.