Vibration Sensors For Pumps

This measures velocity mm sec peak or rms to detect unbalance and problems with structural rigidity and or foundation.

Vibration sensors for pumps. For vertical measurement sensors should be located on the motor and pump drive end bearings. 4 20 ma corresponding to 0 50 mm s 0 1 97 inch s. Wireless sensors attached to the pump measure temperature and vibration in three axis and allow to optimize preventive maintenance and enable troubleshooting. Hermetic sensors used for protection against pump cavitation recirculation and resonance.

Pumps sensors vibration overview solutions documentation tools. There are dozens of different types of pumps and a seemingly endless list of applications but industrial accelerometers can often help the maintenance professional to diagnose sometimes tricky issues with pump operation. How to choose vibration sensors for rotating equipment. Protects against harmful vibration.

Many facilities want to monitor pump vibration but do not want an expensive vibration program. An introduction to our sulzer sense condition monitoring. 4 20 ma sensors output overall vibration levels so that maintenance professionals can take action on pumps that indicate abnormal or increasing vibration. As the pump started the sensor monitored the high frequency vibration signals represented in figure 2 by the section of the graph where the vibration level is just above the 4 ma level.

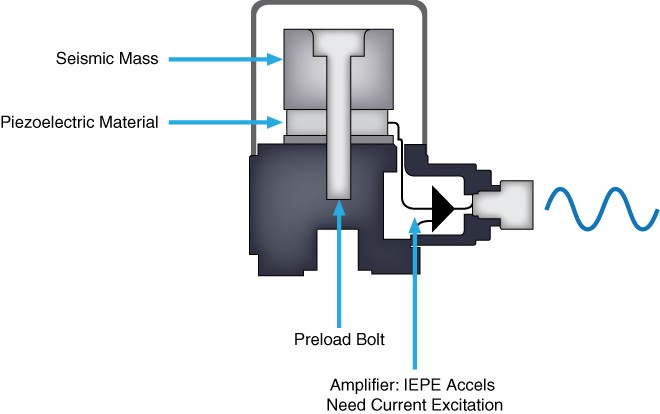

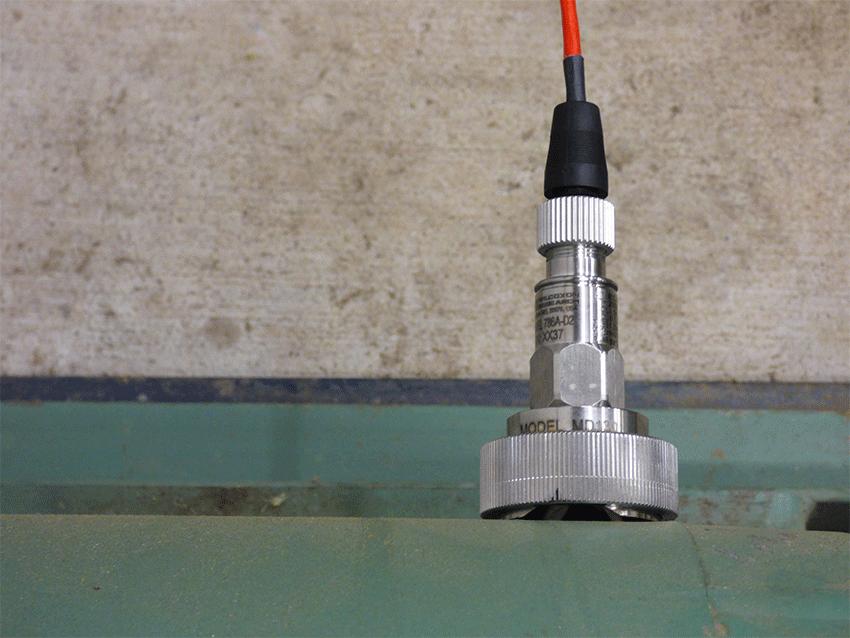

13 vibration monitoring of pumps august 2012 wilcoxon sensing technologies proprietary. The vibration sensor that is for the application will depend on the frequencies of interest and the type of pump being monitored. For horizontal measurement vibration sensors should be mounted on the motor bearings and pump bearings. When it comes to rotating assets such as fans blowers pumps cooling towers and other equipment powered by ac induction motors vibration analysis is an effective diagnostic tool.

Most pumps can operate from 450 to 3 600 cpm 7 5 to 60 hz depending on site pumping requirements available horsepower drive and gearing. Physical characteristics such as temperature rating size and connector orientation are also considerations. The pump was brought up to speed at 359 rpm. The range of vibration sensors offered is wide as a vibration sensor has many different characteristics that may vary including measurement related factors such as frequency response sensitivity and accuracy.

A vacuum pump attached to this pump s input provided the means of controlling the input head of the test pump.