Virtek Laserqc Calibration

Virtek trusted by the world s top tier aerospace and composite based manufacturers for best in class laser positioning solutions will showcase its newly enhanced all in one solution virtek iris 3d with vision positioning system vps and high visibility laser at camx 2019.

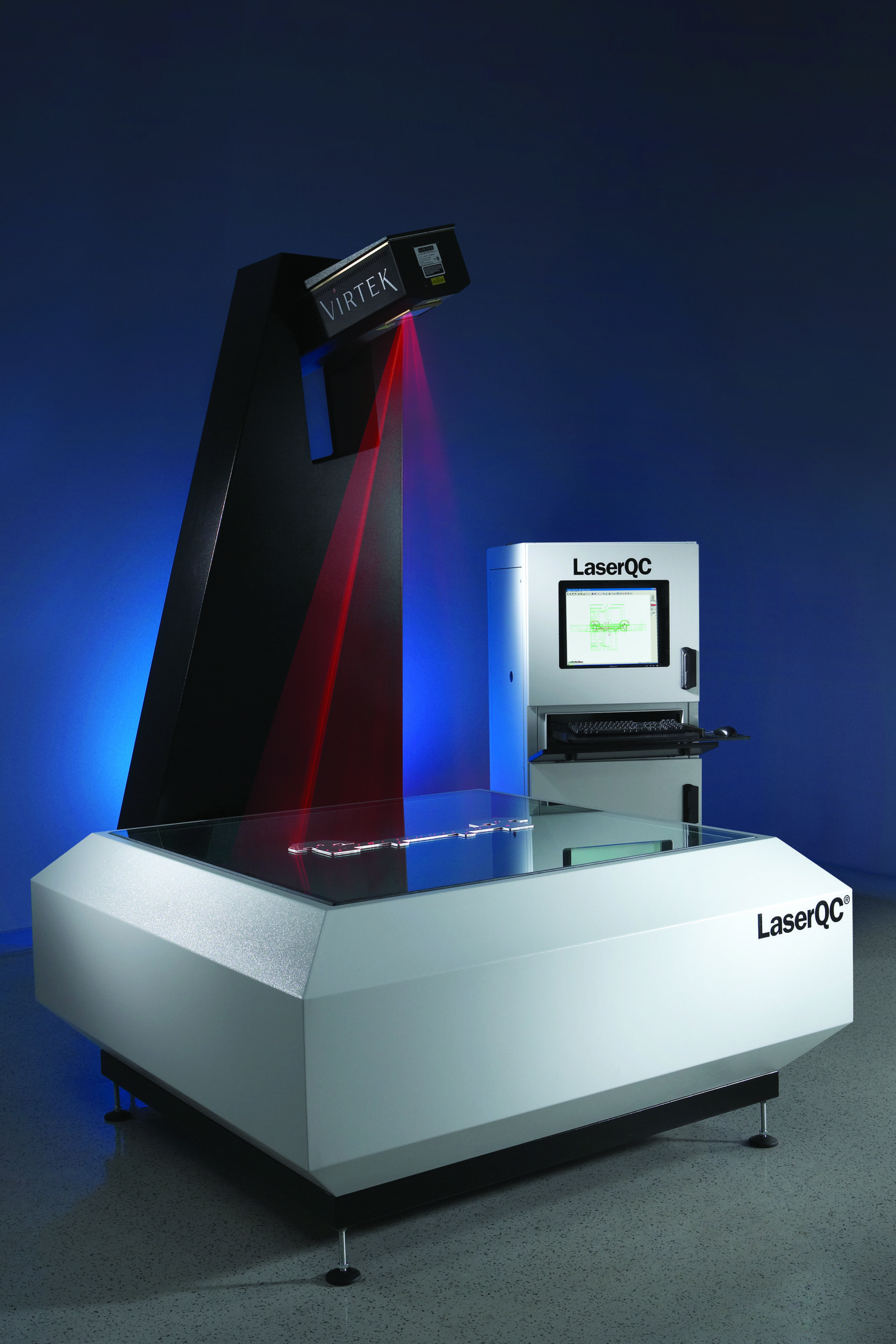

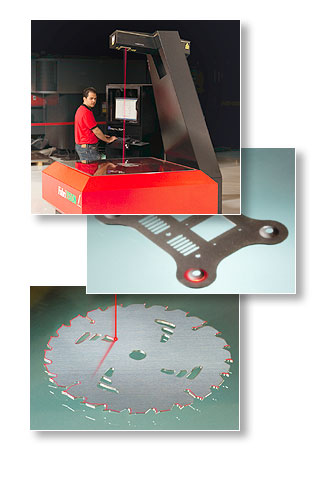

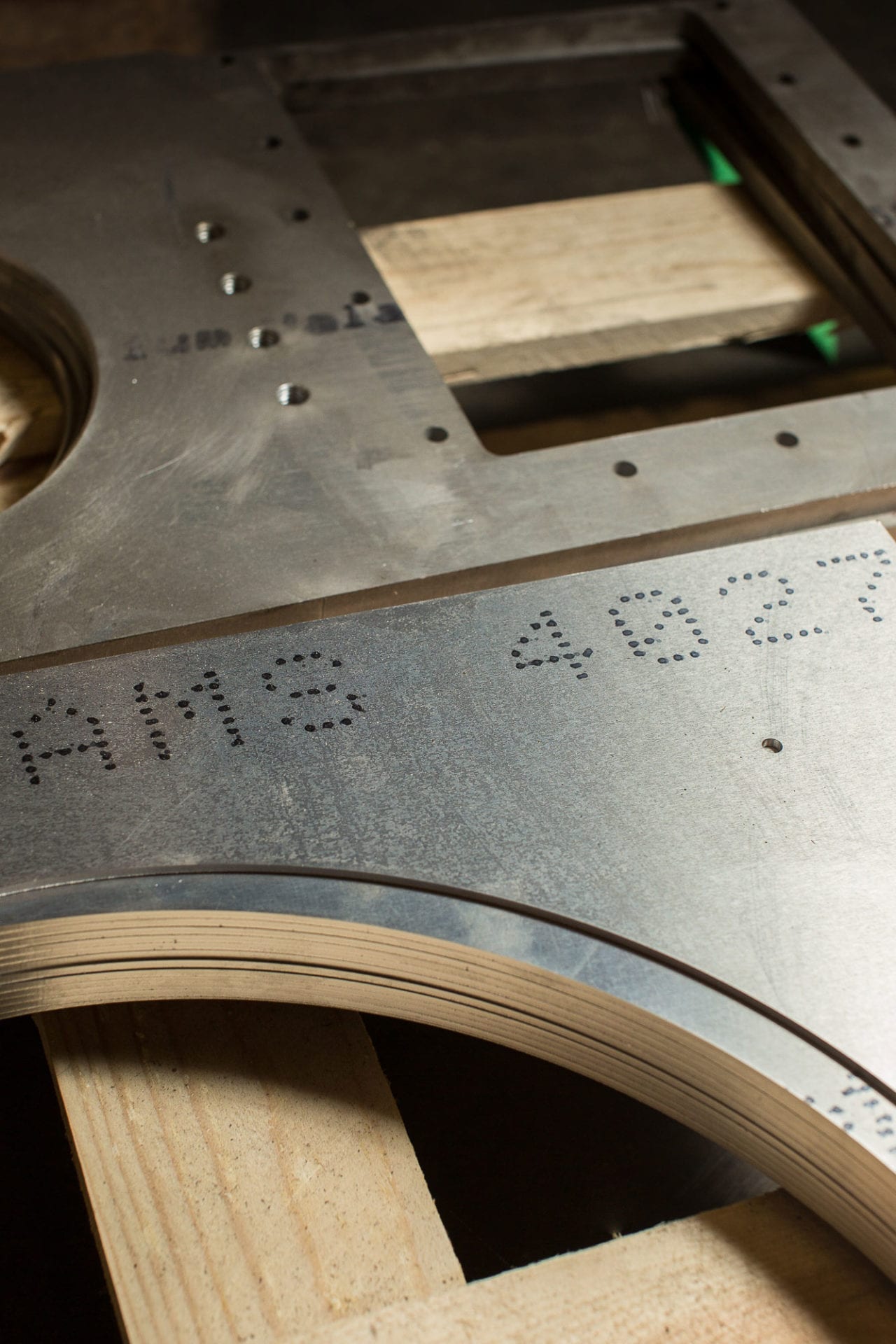

Virtek laserqc calibration. Virtek laserqc is a rapid inspection system that employs lasers to measure the accuracy of two dimensional parts to tolerances within 0 05 mm 0 002 inches. Laser qc dramatically increases throughput in precision sheet metal tubing precision foam leather aerospace and gasket fabrication. Calibration repairs vitrek is pleased to provide world class customer support before during and after the sale. Virtek laserqc afm is designed for the manufacturing environment.

Laserqc benefits laserqc is the premier self calibrating laser inspection system in its class. Our team of field service representatives application specialists and remote support professionals have amassed years of best practices working with companies like yours and can help you get the most from your investment. Our highly skilled factory service technicians take pride in getting the job done right and providing standard cal repair turnaround times that are among the fastest in the test equipment industry. Designed for the manufacturing environment virtek laserqc verifies system calibration before each scan to ensure repeatable accuracy.

Virtek vision international ulc is a market leader in laser projection and quality inspection systems improving productivity and reducing cost. Virtek laserqc verifies system calibration before each scan to ensure repeatable accuracy. Our global service organization helps ensure that your virtek systems are always optimized for maximum performance. Virtek laserqc automatic form measurement afm is a rapid inspection system that employs lasers to measure the accuracy of three dimensional parts to tolerances within 0 25mm 0 010 inches.

It verifies calibration before each scan to ensure repeatable accuracy. Identify quality issues quickly. Identify quality issues quickly.