Vlf Cable Testing Procedure

Perform the test as instructed to make best use of vlf technology.

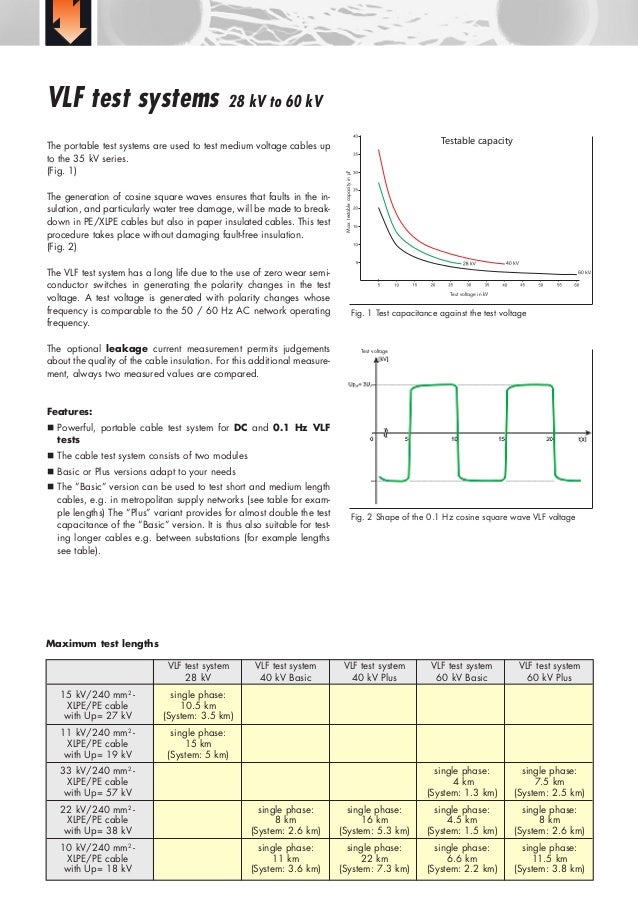

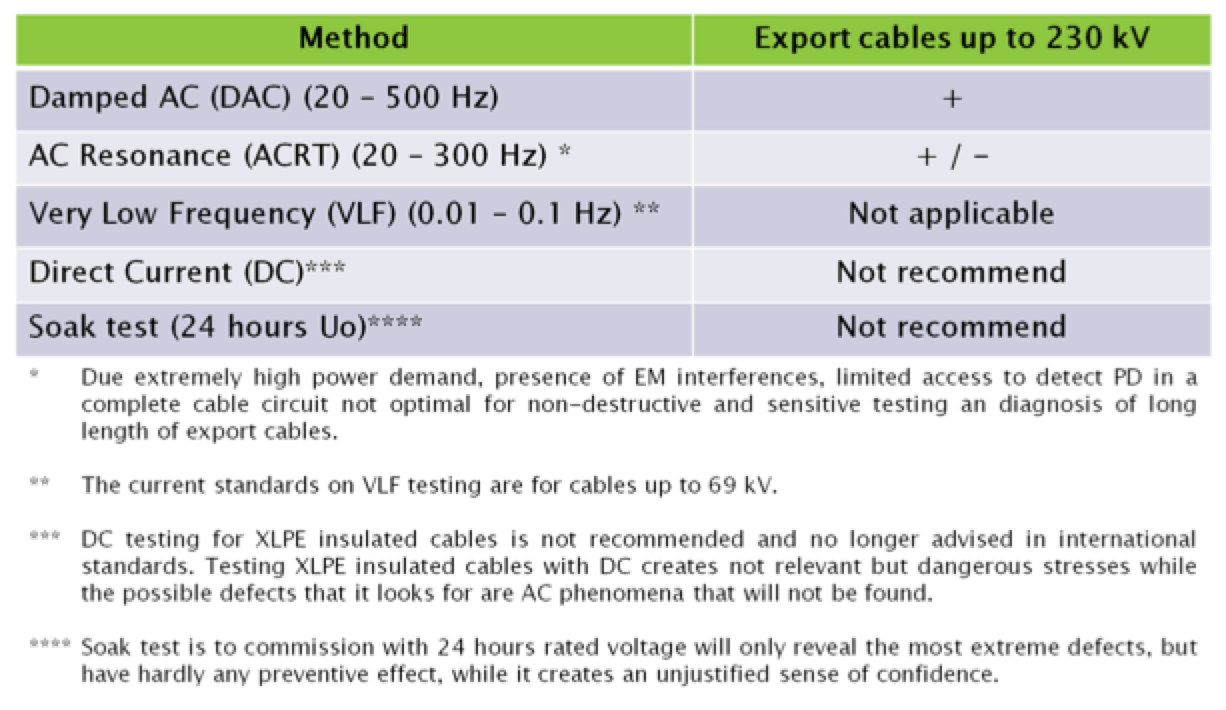

Vlf cable testing procedure. The benefits of vlf maintenance testing regular routine maintenance testing of aged cables has been demonstrated to reduce the chance of unscheduled failure to approximately 10 of the failure rate that might be encountered without such testing. Very low frequency vlf withstand testing is the application of an ac sinusoidal waveform generally at 0 01 0 1 hz to assess the quality of electrical insulation in high capacitive loads such as cables. Vlf testers are smaller and more practical than ac testers but output the same amount of power as a 50 hz mains device. If a vlf test is too low in voltage and or too short in duration more harm than good may result.

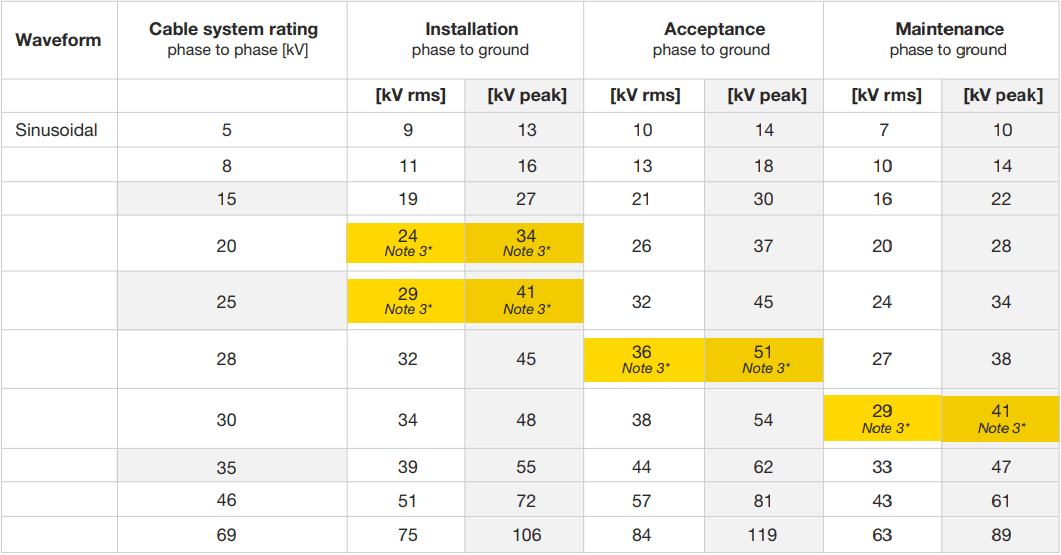

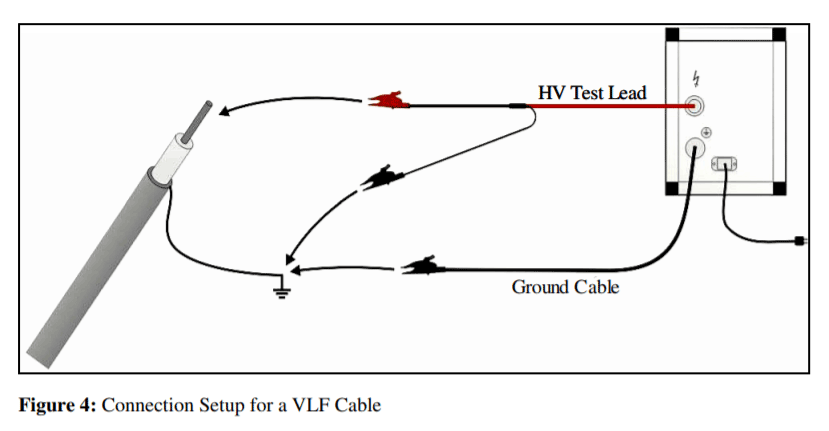

During the test cables are subjected to a test voltage significantly higher than what they experience during normal operating conditions. In accordance with respective standards sine wave voltage is used for vlf testing. This combination of size and power makes very low frequency cable testing perfect for testing longer sections of cable and apparatus. While the testing procedures of the past dc testing were sometimes actually damaging to the cable insulation modern vlf.

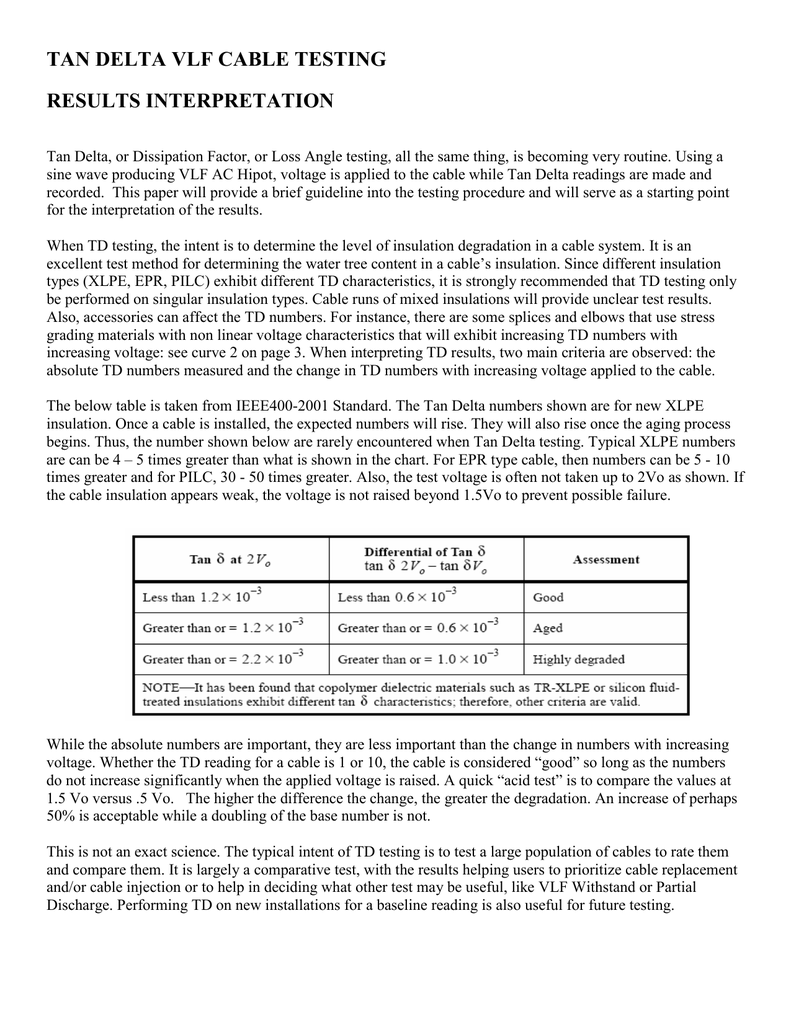

The preset test time in the range of 15 to 60 minutes is short and economical. Very low frequency vlf tan delta testing is a precise and non destructive method to provide information on the extent of ageing in cable insulation. We need to apply 1 414 times 11 1 414 15545 volts dc of voltage between phase to phase or between phase to earth. Thus it is quite natural for utilities to also use withstand and partial discharge tests as commissioning and maintenance tests for cable.

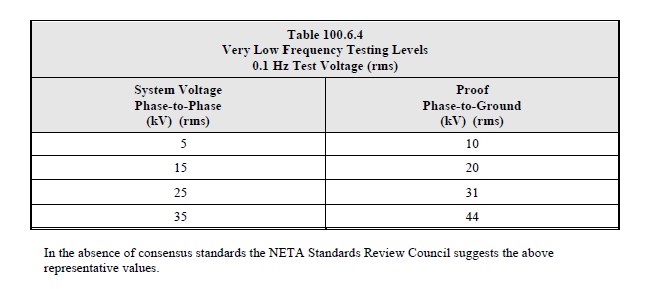

When vlf withstand testing cable the proper test voltage and time duration are critical for the success of the test. A very low frequency vlf withstand test is an ac withstand test usually carried out at a frequency between 0 1 hz and 0 01 hz. They are in the range of 1 5 u0 to 3 u0. The procedure for vlf testing is nearly identical to that of dc hi pot testing and is also conducted as a go no go test.

Vlf testing uses very low frequencies as part of an ac cable maintenance routine. Approximately 12 of cables fail during the test and cable repair can then be done in a planned manner. Once partial discharge is triggered in a defect under the test. Voltage levels are a multiple of the nominal voltage of the cable.

This kind of test is suited for testing high capacitance loads such. High voltage withstand tests are used in conjunction with partial discharge measurements on solid dielectric cable and accessories within manufacturing plants to ensure the quality of completed cable system components from mv to ehv.