Water Jet Vs Laser Cutting Cost

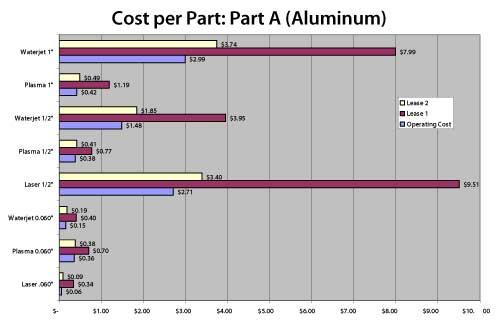

Waterjet is usually the most expensive to operate due to the need for consumable abrasives.

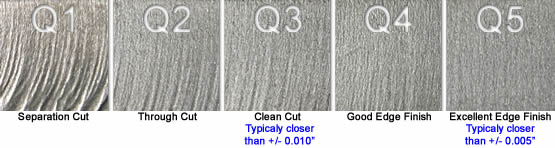

Water jet vs laser cutting cost. Waterjet cost factors operating costs. Co2 cnc laser tables can cost between 12 20 hr to operate. As for their processing tolerance it is of approximately 0 002 0 05 mm for laser cutting and 0 008 0 2 mm for water jet cutting. When cutting thin materials with laser very high cutting speeds can be achieved which can help to reduce the cost per part.

Depending on the pump capacity and cutting depth waterjet cutters cost between 20 40 hr to operate. Plasma is the most limited. Laser cutting for your custom metal project may be a perfect fit for our shop. Waterjet cutting is by far the most flexible of these 3 cutting processes because it can cut almost any material.

A laser cutter is more accurate than a water jet in most instances with a cut tolerance as little as 002. Laser cutting is much more precise than waterjet cutting. Laser cutters do well with materials that range between 0 12 and 0 4 in thickness and are commonly used to cut flat sheets of medium thickness. 4 laser cutting vs.

It can only cut conductive metals and is really only practical for mild steel stainless steel and aluminum. The choice of whether to use waterjet or laser for your next cutting job depends entirely on what your specifications are. Waterjet is both slow and costly to run making it the least productive system to operate. Because fixed tooling and fixturing are generally not required in either cutting process set up costs are minimal for both.

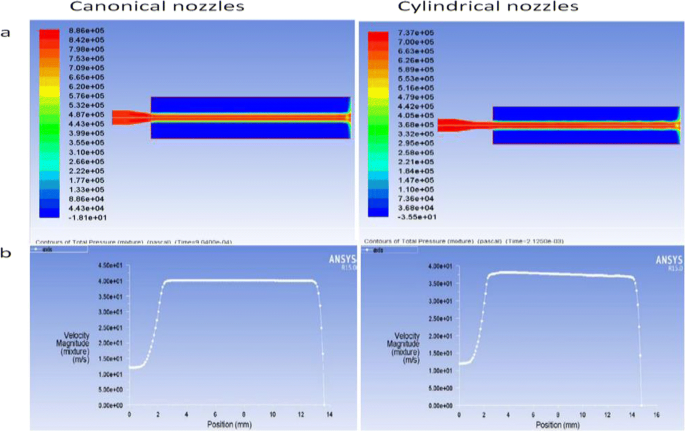

Fiber cnc laser tables can operate between 10 18 hr. Laser cutting involves the use of a laser to melt burn or vaporize material. The cutting path of a laser is much thinner than a water jet which can be a benefit when cutting tight geometry on small parts or when components need to be nested close together. When your job calls for metal custom laser cutting maximizes uptime while minimizing costs.

The laser can be static or move across the material. The minimum size of the cutting slit is 0 006 0 15 mm for laser cutting and 0 02 0 5 mm for waterjet. Such abrasives cost around 0 25 lb. During the process a focused beam of light is used for the cut.

However there is one clear winner when you compare laser cutting vs. Laser is limited to metalics some plastics and fiberglass some fabric. This method of processing is mostly used for stainless steels or steel metals up to 5 8 thick.